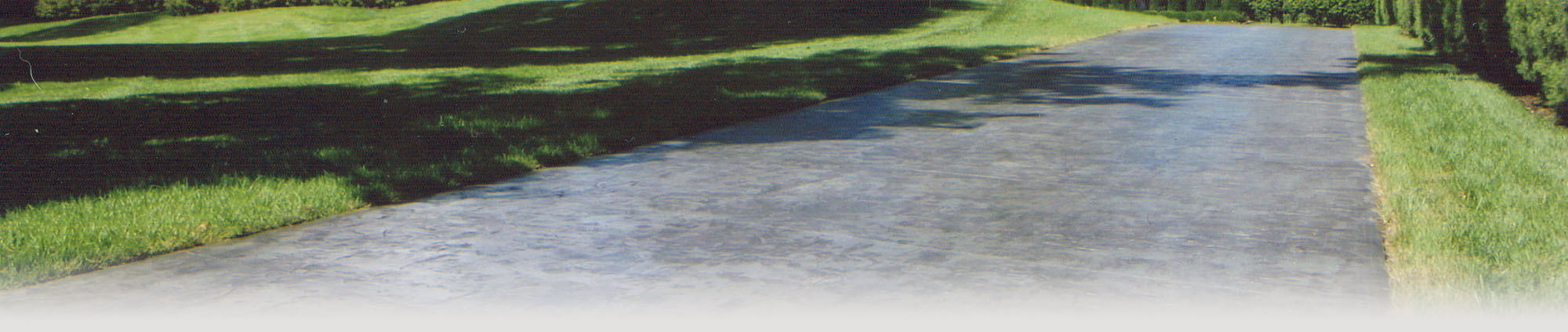

Concrete Driveways

We want your next driveway to be your last!

At B & W Concrete Services, our goal is to build concrete driveways that stand the test of time. It's unfortunate, but flatwork tends to be very price driven and often priced & installed with that in mind. It does not cost that much more to install it the right way. Often homeowners are not provided with information about how to properly maintain their concrete driveways. These practices combined with our 42 average freeze/thaw cycles per year in the Midwest wreak havoc on exterior flatwork. Concrete that has not been installed or maintained properly is far more susceptible to the negative affects our winters can have on it. We strive to give your concrete every chance to stand up to Mother Nature's forces starting with how we go about installing it and then by arming you with all the information you will need to understand and maintain it. This leads to a superior, more durable, higher quality finished product.

Our Process

We will start by providing you a free estimate. We can bid per the specifications on the plans you provide, per your direction, per our recommendations or any combination of the three. There are no written rules with flatwork about what is right or wrong practices. There are a lot of opinions - common methods & cheap to very expensive ways to go about installing it. We base our recommendations off our experience and what has proved to have been successful over the years.

When you're ready to start...

We will ensure your sub-grade is correct and ready for concrete placement. Your concrete is only as solid as the ground it is sitting on. We utilize a rock base and thoroughly compact it to avoid settling and shifting after your concrete is poured.

We will set the benchmarks and forms to make sure water will drain properly. Unreinforced concrete driveways or use of fibermesh in the mix are common practices in this area. We recommend and utilize steel reinforcement. This provides you the most structural integrity for your driveway and in the event you get a crack, it will hold everything together and keep the crack to a minimum.

When we are ready to pour, we will pour a high quality mix design. The mixes we pour will meet or exceed industry standards for compressive strength and air entrainment. Weather conditions, temperature and humidity can have a significant impact on how a concrete mix will behave. Our experience allows us to work closely with our suppliers to tweak the mixes and ensure they will act how we want them to while we are finishing.

We will incorporate proper finishing techniques, while doing everything possible to control and prevent cracking. "Shrinkage cracking" occurs in all concrete when it becomes hard or hydrates and moisture evaporates. We attempt to control where concrete is going to crack by installing proper control joints, zip strips &/or saw cuts in predetermined locations to give it a place to crack and better maintain a driveways aesthetics. In extreme weather, we will use a chemical barrier to hold moisture in, preventing it from evaporating to rapidly. This minimizes the chances of a crack occurring while the concrete is still setting up (plastic shrinkage cracking).

After the job has been poured, we will educate you on what to expect and how to properly maintain your new investment.

Concrete Driveway Cost

We want to look at every job for what it is, evaluate what we would have into it and price it accordingly. Not all jobs fall into a SQFT price and we don't price them that way. We do have a price range & SQFT budgeting numbers we can provide, but your job may be affected by a number of factors we want to look at before submitting our written proposal. This provides you a very thorough, accurate upfront estimate.